Corporate Sustainability Strategy

Sustainability at the heart of corporate strategy

For Interzero, sustainability is at the heart of its corporate strategy. All our activities are part of our vision – a world without waste.

Vision and mission: a world without waste

With our vision of a zero-waste future, guided by our sustainability strategy, we are developing new concepts for an integrated circular economy. We always follow our mission: as a leading partner for customers in the circular economy, we close cycles in every industry, avoid waste and conserve resources by developing tailored, integrated environmental solutions.

Our sustainability strategy: zero waste solutions

no waste of ideas

no waste of resources

zero waste solutions

Successful transformation processes thrive on innovation. We test every idea that brings us closer to closed cycles - even at the risk of failure. This is the only way to create the disruptive change our linear economic system needs.

We support our clients in professionalising their sustainability practices and integrating sustainability into their reporting processes. To achieve this, we are fully exploiting the potential of digitising our services.

To extend the life of our products, we are opening new markets and expanding the business models we have developed to achieve annual sales growth.

To enable industry and commerce to use resources more efficiently than ever before, we are working with our customers to develop new design approaches for recycling.

From our point of view, the only sustainable use of resources is that which does not produce any waste. That's why every day we are looking for new ways to close cycles.

To save the planet from plastic waste in the long term, we develop new plastic recycling solutions every year. We are also increasing the quality and quantity of secondary raw materials we produce from plastic waste and offer to industry for further processing.

To limit global warming to below 2 degrees, global resource consumption must be decoupled from economic growth. To this end, we are closing new material and logistics cycles to save at least 5 million tonnes of raw materials and 800,000 tonnes ofCO2 every year.

To significantly reduce the per capita environmental impact of waste, especially in cities, we are fully committed to avoiding waste and significantly increasing material recycling rates.

Our employees and their skills are at the core of our competence as an environmental service provider. To work optimally for our customers every day, a consistent commitment to their health, motivation and further development is needed.

We want to promote the physical and mental health of our employees and reduce our sickness, accident and turnover rates below the industry average. To do this, we create a safe, value-driven, innovative and development-enhancing work environment.

We want to make the full and effective participation of all - regardless of age, gender, background, religion or social status - a reality at all levels of decision-making. That's why we want to ensure that all (potential) employees have as many equal opportunities as possible in our company.

Developing a full circular economy requires that we share our experience and knowledge - not only with our customers, but in all areas of the economy and society. This is the only way to properly convey the ecological and economic benefits of effective recycling management.

We see our role as promoting sustainable lifestyles and consumption habits. As a facilitator, we ensure that knowledge about the circular economy is built in education, politics, business and society.

We want to develop cross-industry approaches and standards for circular economy solutions and scale them up (internationally). To achieve this, we work closely with our partners, stakeholders, suppliers and customers.

At the same time, we create the freedom for our employees to participate in relevant initiatives to develop circular economy solutions.

no waste of talent

no waste of knowledge

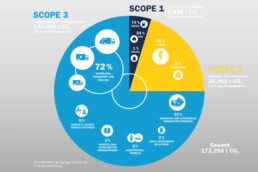

Our climate strategy: 50% fewer emissions on site by 2025

Our services help our customers save greenhouse gas emissions and resources. But our own business activities also generate CO2 emissions. Our aim is to reduce emissions on the ground to contribute to the climate goal agreed at the 2015 UN Climate Change Conference – limiting global warming to well below 2 degrees. To this end, we design our own processes and activities to be as resource-efficient and effective as possible. Based on the calculation of our corporate carbon footprint, we have developed a climate strategy and concrete targets:

- 50% on-site emission reductions (Scope 1 and 2) by 2025

- Continuously looking for optimisation potential in logistics and working to reduce the resulting emissions

- Annual savings of at least 5.5 million tonnes of resources and 800,000 tonnes of CO2 equivalent through own services

Related sites

Studies and certificates

Together with the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT, we regularly study the positive ecological effects of our activities on the environment.

Contact

info@interzero.si

Pre-inspections

Pre-inspections

Interzero provides companies with a comprehensive expert overview of the management of placed on the market packaging and packaging waste.

Check that you meet all your legal obligations

We will arrange a time to visit with you to check:

- contract documents

- records,

- a waste management plan

- reports,

- statutory declarations of packaging compliance and inclusion in the common scheme.

If you are also an end-user (collecting non-municipal packaging waste in your yard), we will also check your separate collection status, records of packaging waste delivered, and record sheets.

These pre-inspections are a preparation for an inspection and are well received by companies, as they provide additional confirmation that you are doing the right thing. correct any deficiencies.

We invite you to watch the webinar where in a 60-minute training session, former environmental inspector Ms. Poljanec Perič explains everything from the course of the inspection to the fulfilment of the obligations imposed by the inspector.

Contact

info@interzero.si

About Interzer

Join us in creating a zero-waste future. With our Zero Waste solutions.

Made for Circle

MADE FOR CIRCLE

Interzer's solution for developing sustainable packaging for your products

Sustainable and environmentally friendly packaging at the point of sale has a direct impact on the purchasing decision.

Made for Circle offers you expert support from the start of the packaging development process to the implementation of a sustainable packaging solution. The key to Made for Circle is that the content and scope of the service is fully tailored to you and your needs.

The overall process of developing sustainable packaging looks like this and takes about 12 weeks:

Results of the completed service:

– Analysis of the recyclability of packaging, used and alternative materials and overview of packaging suppliers and manufacturers

– Technical report on customer expectations and detailed information on optimisation solutions

– Sustainability impact assessment and life cycle assessment of packaging

– Certification of packaging with the ‘Made for Recycling’ seal on customer request

Contact our team for any questions about the offer!

M + 386 01 560 91 50

Contact

Rules of conduct for the collection of waste products

End-user obligations

Packaging waste rules

Management of packaging waste that is municipal waste

End-users – households must collect packaging waste, which is municipal waste, in dedicated containers and store it and hand it over to the public service operator, in accordance with the regulation governing the compulsory municipal public utility service for the collection of municipal waste.

Other end-users can send separately collected packaging waste generated as municipal waste from trade, industry, craft or service activities to a packaging waste management company.

Management of packaging waste other than municipal waste

Distributors and end-users must prepare packaging properly before submission, which means that each packaging fraction must be collected and emptied separately to ensure that it does not contain residual substances. Packaging that is not properly emptied and contains residues of the substance shall be treated as residual packaging.

Properly emptied waste packaging means that it is drip-free, free from leakage, dust, clunking and no visible residue, except for the inevitable layer on the packaging itself, with no dried residue at the bottom. Residue fraction or impurities shall not exceed 5% of the total amount of the separately collected fraction of packaging waste collected.

Other provisions:

- Packaging waste that is not municipal waste may not be handed over to the public service operator as mixed municipal waste or as a separately collected fraction of municipal waste.

- The end-user must return non-municipal packaging waste to the distributor or hand it over to a packaging waste management company .

- The end-user may leave non-municipal packaging waste generated in the course of a commercial or service activity with a public service operator in accordance with the regulation governing the compulsory municipal public service for the collection of municipal waste.

- In the case referred to in the preceding paragraph, the end-user who is a catering or tourism operator with a capacity of 5 000 overnight stays or more per year shall itself provide special containers in which it shall leave the separately collected fractions with the public service operator separately from the waste of other municipal waste producers.

- Until such time as it is disposed of, released or returned in accordance with this Regulation, the end-user shall keep packaging waste which is not municipal waste separate so that it does not mix with other waste and so that it can be collected and reused, recovered or disposed of in accordance with the rules governing the management of waste.

Management of packaging waste that is hazardous waste

Packaging waste is classified as hazardous waste if the packaging material has the characteristics of hazardous waste, if the packaging waste contains residues of or is contaminated with hazardous goods.

Packaging waste shall be considered free from residues of, or contamination by, dangerous goods if:

- the inside of the packaging waste of a viscous dangerous good scraped off with a spatula or brush so that the remaining quantity of the good is no longer usable,

- the packaging waste of a liquid dangerous good is emptied so that it does not drip, o the packaging waste of a solid dangerous good is emptied so that no residues of that good can be shaken out, or

- the waste packaging with the expelled gas no longer emits expelled gas or no residues of dangerous goods are circulating in the packaging.

Notwithstanding the preceding paragraph, where the packaging of dangerous goods is accompanied by instructions from the manufacturer of those goods on the environmentally safe emptying of the packaging, that packaging shall, if emptied in accordance with those instructions, be deemed to be free from residues of, or contamination by, dangerous goods.

The end-user must dispose of packaging waste that is hazardous waste:

- be handed over to a hazardous waste collector in accordance with the waste regulations, if the packaging waste is non-municipal waste,

- to be handed over to a public service operator in accordance with the regulation governing the compulsory municipal public service for the collection of municipal waste, if the packaging waste is municipal waste.

- the provisions of the preceding paragraph shall not apply where the release or disposal of packaging waste containing or contaminated with residues of dangerous goods is regulated by a specific regulation.

Rules of conduct for the collection of waste electrical and electronic equipment

The end-user, who is an individual, disposes of WEEE from households:

- to the public service operator:

- at the collection centre,

- in a mobile collection facility for hazardous fractions if the WEEE is very small household WEEE, or

- to the collector at the collection point,

- to the distributor at its point of sale or collection, if the WEEE is the same as the delivered WEEE in terms of intended use and WEEE class classification, and the number of pieces of WEEE is the same as the number of pieces of delivered WEEE. The exception is lamps, which can be handed over to the distributor without the obligation to buy new lamps.

The end-user, who is a legal person, a sole trader or an individual self-employed, delivers WEEE from households to a collector. The end-user shall hand over the non-household WEEE to a collector.

The end-user shall, before disposing of or transferring WEEE, keep it separately so that it is not mixed with other waste, damaged or contaminated by hazardous or other substances and its reuse or recovery is not prevented or not feasible except at disproportionately high cost.

Where WEEE contains substances or materials which, before being dismantled, must be disposed of in accordance with the rules governing the disposal of those substances or materials, the end-user shall ensure that the WEEE is in such a condition at the time of its release or disposal that the disposal of those substances or materials can be carried out in a prescribed and safe manner.

If WEEE from households is damaged to such an extent that it poses a risk to the environment and human health due to hazardous substances in it, is without important components, or is contaminated with other waste, the end-user can only hand it over to the public service operator at the collection centre.

WARNING! Electronic waste such as gas lamps, televisions, LCD screens, fridges, chests contain substances that are harmful to human health and the environment!

Rules on the management of waste batteries

The end-user shall not leave waste portable batteries and accumulators with the public service operator as mixed municipal waste.

End-user waste portable batteries and accumulators:

- leaves it up to the distributor of portable batteries and accumulators,

- left with the public service operator in collection centres for separately collected fractions of municipal waste or in mobile collection facilities for separately collected hazardous fractions of municipal waste, or

- handing over to a collector of waste portable batteries and accumulators.

The distributor shall take back waste portable batteries and accumulators free of charge at the point of sale from any end-user to whom he wishes to hand them over, even if the end-user is handing over waste portable batteries or accumulators from a manufacturer other than the manufacturer of the portable batteries and accumulators sold by the distributor at his point of sale, or if the end-user has no intention of purchasing portable batteries or accumulators.

Automotive and Industrial batteries are either left with distributors or handed over to authorised collectors.

WARNING! Waste batteries contain heavy metals (lead, cadmium, mercury, etc.) and other hazardous substances (acids) which, if not handled properly, can harm human health and the environment!

Rules on the management of waste funeral candles

Waste tombstone candles are collected separately and temporarily stored on or next to the cemetery as a separate fraction of municipal waste in dedicated containers and left with the public collection service provider separately from other waste from the cemetery.

Waste tombstone candles must not be crushed, compacted, contaminated or mixed with other waste.

Contact

info@interzero.si

Waste batteries and accumulators management

Waste batteries and accumulators management

Interzero has set up a system for the collection, treatment and recycling of waste batteries and accumulators in Slovenia. By joining the common Waste Battery Management scheme, you can delegate all your obligations to Interzero.

Who is liable?

The person liable for the regulatory management of waste batteries is a legal person registered in the territory of the Republic of Slovenia who comes into contact with waste batteries at any time during their lifetime.

What are the liable entity’s obligations?

PRODUCERS, ACQUIRERS AND IMPORTERS

- transfer of the obligation to handle waste batteries and accumulators to the common scheme

- joining to the common scheme

- keeping records of waste batteries

- registering your activity with FURS

- entry in the register of producers of waste batteries at the ARSO

- semi-annual reporting to the Common Scheme Operator

- paying for the management of waste batteries and the environmental levy

THE OBLIGATIONS OF BATTERIES DISTRIBUTORS

- free collection of waste batteries from households

- appropriate labelling of products

END USERS

- appropriate collection of waste batteries, separate from other waste

- correct submission of the waste batteries to the carrier or collector

Our experts will be happy to suggest the best solution for you or to make an individual offer. Fill in our contact formor give us a call!

Why choose Interzero as your waste collection partner?

Optimal and legally compliant collection

Recycling of collected waste batteries and accumulators

Informing and raising end-users' awareness on the correct management of waste batteries

Marking of traders' collection points

Collection of full containers

A full container for waste batteries and accumulators? Order a collection:

Contact our sales team for any questions about the offer!

T +386 1 560 92 02

Contact

About us

With our Zero Waste solutions, we ensure a waste-free future

Circular solutions

Close the material loop and save

Integrated material flow management - your competitive advantage

As raw materials become scarcer and more expensive, the operational management of material flows is becoming increasingly important for companies. Interzero experts develop integrated waste management concepts for the retail, industrial and service sectors to reduce material flows in production, reduce environmental impact and return used raw materials to the business cycle.

Production waste, organic waste, hazardous substances, outdated transport packaging – many types of waste are full of potential in terms of resources and cost savings. Whether you are a large corporation, a small or medium-sized business, it pays to look closely at how much waste you generate and reduce it to an absolute minimum. Interzero’s specialist experts help you with a circular solution, by analysing your material flows in detail and ensuring a consistent separation of the different types of waste. This makes sorting faster and easier, increases the value of the individual waste fractions and facilitates the recycling of the raw materials contained in the waste.

By working with around 800 certified recycling companies, Interzero can extend its services beyond the company’s production plants and premises to entire networks of branches and workshops in retail and industry. Instead of purchasing new, secondary raw materials are reused in companies’ own production processes.

For example, automotive groups currently sell scrap metal from their own production and then have to buy fresh metal at the same time. In these cases, Interzero takes responsibility for material handling and logistics, ensuring that the raw materials remain in possession of the customer. The result is a closed loop of material recycling that is constantly starting again.

Closed waste loop concept

Interzero, Alpla and Donat have successfully implemented the closed waste loop concept in Slovenia, which allows Atlantic Droga Kolinska to reuse its packaging waste even after it has been discarded by the consumer. Interzero provides a set amount of waste PET green plastic packaging to the full-cycle system (green to green), recycles it with the help of partners, and creates a new 100% recycled plastic bottle. The quality and quantity of recycled materials recovered directly depends on the quality of the work done with the product at each stage of its life cycle – from sourcing and product design to marketing, use and, finally, recycling of the waste material.

Contact our sales team for any questions about the offer!

T +386 1 560 92 02

Contact

Waste abroad

Consultancy for waste managment abroad

Is your company focused on exporting and selling products abroad? Are you aware of your legislative obligations in the field of waste management for products you sell abroad?

We will do our best to provide you with all the information you need on environmental legislation abroad

Many companies have complex international sales networks. It is a challenge to manage packaging legislation across networks and national borders, as each country adapts its directives to the market. Each law has different levels of stringency, and often companies operating in countries with less developed systems are not aware that they need to ensure compliance.

The combination of these factors can lead to non-compliance with the law, resulting in significant costs, fines or even imprisonment.

Interzero has an international presence, so we have an excellent knowledge of the legislation on waste products abroad. We have compiled key information on waste product legislation in 28 European countries, Canada and Turkey.

We offer advice and assistance in implementing all packaging waste management obligations in Austria, Italy and Germany in accordance with the current legislation in each country. For packaging waste management in other countries, please send us an enquiry.

Do you supply your products to Germany?

Online stores based in Europe or elsewhere that supply their products to consumers in Germany must comply with the new German Packaging Law. The new law applies to retailers who sell their goods in sales packaging to customers in Germany.

For more information on packaging licensing in Germany, please contact Interzero Slovenia or visit the “Lizenzero” website where you can register your packaging and comply with the legislation: www.lizenzero.de/en.

Contact

info@interzero.si

About Interzero

Join us in creating a zero-waste future. With our Zero Waste solutions.

Packaging analysis and optimisation

Packaging development: from analysing the recyclability of your packaging to optimised packaging - Interzero supports you all the way!

Our vision is a future without waste. To achieve this, we offer a wide range of solutions that save resources and ensure that the cycle is closed. From the analysis of your packaging through “Made for Recycling” to the packaging optimisation process “Made for Circle” to other laboratory services we can provide for you at the Competence Centre for Laboratory Services in Maribor.

Choose your tailor-made analysis or optimisation solution

Check for recycling: checking the recyclability of your packaging

We analyse the recyclability of your packaging with a software tool to identify collection, sorting and recycling options.

Made for Recycling: your analysis of recycling options

Want to know how recyclable your packaging is? Find more information and our offer here!

Optimising packaging with Made4Circle

From analysis of the right raw materials and prototyping to optimised packaging including certification.

Centre of competence for Laboratory Analysis

From various laboratory analyses to our own production of plastics for individual recycling.

Comparison Made for recycling vs. Made for circle

Made for Recycling - analysis of recycling options

As the name suggests, Made for Recycling is about recyclability of your packaging. This is a scientifically based evaluation method developed together with the BIFA Environmental Institute and tested by experts from the Fraunhofer Institute for Process Engineering and Packaging IVV. This packaging analysis is carried out in Maribor at the Interzero Competence Centre.

With a very good recyclability, your packaging can be certified with the“Made for Recycling” seal of approval. This way, you also demonstrate your sustainability commitments to your customers!

What if your packaging does not meet these standards?

This is where “Made for Circle” comes in. We work with you to design your packaging so that we can ensure optimised packaging on completion.

Made for Circle - start optimising

The packaging optimisation process can be divided into a total of 6 phases, which are modularly configured for you. In the first phase, we analyse your packaging to check for recyclability, using the already recognised Made for Recycling process.

At the end of the whole process, after successful optimisation, we offer you the possibility of certification, which is visible with the“Made for Recycling” seal of approval.

About Interzero

Join us in creating a zero-waste future. With our Zero Waste solutions.

Contact

info@interzero.si

Meaning of waste product labels

Meaning of waste product labels

Meaning of the labels on the packaging

The Mobius loop appears in various forms and means that a product or packaging can be recycled or indicates a product that is already made from recycled materials. Each link represents a part of the recycling chain: collecting, converting into a new product and buying the recycled product.

The circle symbol is used for packaging that is made partly or entirely of recycled material. The percentage is indicated in the code.

The arrows indicate that the product is intended for multiple uses, such as returnable bottles.

The sign indicates that the product must be disposed of separately. It occurs mainly on electrical and electronic equipment.

The sign reminds you to dispose of the packaging in a suitable place.

A Mobius loop with a number and an abbreviation indicates a specific type of packaging material. The codes and abbreviations are laid down by law in Decision 97/129/EC.

The European Union awards the EU Ecolabel to products that reduce negative environmental impacts, contribute to the efficient use of energy resources and a high level of environmental protection, and add value for the final consumer by virtue of their environmental credentials. The criteria for the award of the European Daisy were set by the European Commission in cooperation with various stakeholders.

Packaging that has been assessed by Interzero through advanced laboratory analysis as being good recyclable can be labelled "Made for Recycling".

Read more about assessing recyclability here.

The Check for Recycling label means that Interzero has used its software tool to check the packaging and mark it as good recyclable.

Read more about recyclability testing here.

| Material | Abbreviation | Numbering |

| Polyethylene terephthalate | PET | 1 |

| High-density polyethylene | HDPE | 2 |

| Polyvinyl chloride | PVC | 3 |

| Low-density polyethylene | LDPE | 4 |

| Polypropylene | PP | 5 |

| Polystyrene | PS | 6 |

| Corrugated cardboard | PAP | 20 |

| Uncoated cardboard | PAP | 21 |

| Paper | PAP | 22 |

| Steel | FE | 40 |

| Aluminium | ALU | 41 |

| Wood | FOR | 50 |

| Cotton | TEX | 60 |

| Colourless glass | GL | 70 |

| Brown glass | GL | 72 |

| Paper and cardboard/miscellaneous metals | C/dominant material | 80 |

| Paper and cardboard/plastics | C/dominant material | 81 |

| Paper and paperboard/aluminium | C/dominant material | 82 |

| Paper and cardboard/plastic/aluminium | C/dominant material | 84 |

Meaning of labels on EE equipment and batteries

The crossed-out container symbol means that electronic devices and batteries must not be disposed of

as mixed municipal waste and collected separately.